We offer two patented, pre-engineered, VAV systems that are ready to “Plug and Play” upon delivery,

the VAV Ready Unit® (VRU) and the Delta Zone Control Unit® (ZCU).

The pre-piped turnkey system cuts installation time and cost significantly and saves on overall cost of ownership.

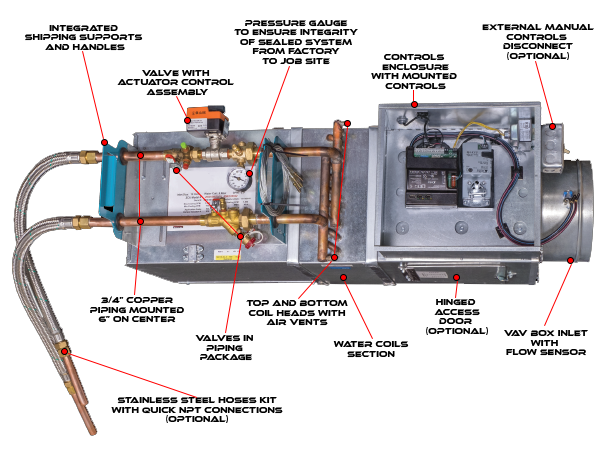

ZCUs and VRUs both come with a pre-pressurized hydronics package (valve, piping, and coil), a pressure gage, and a pre-programmed VAV controller.

Benefits

- Decreases installation cost

- Reduce project completion time

- Increases performance

- Minimizes risk of injury

- Standardizes product components

- Increases LEED® points

- Minimizes life cycle cost

- Decreases field labor

- Mitigates change orders

- Factory commissioned

- Complete, engineered VAV

- Increased profitability/lowest total construction cost

- Quickest construction time

- Drop-shipped to the site location

Fast Turnaround Time

At HVAC Manufacturing & Technology, we use zero accumulation assembly lines to optimize production and custom quick ship programs to accelerate delivery times. Our rigorous testing protocols ensure your VAV unit ships 100% defect free and factory commissioned.

We can ship your VAV units directly to the job site and provide staged delivery to meet your installation schedule without requiring job-site storage. Staging delivery also helps protect the unit from damage.

Unit Installation Is Simple:

- Lift the unit into position

- Connect the inlet and discharge

- Attach the hydronics (supply and return)

- Plug power into the controls

What Makes Our Products Different?

Factory Commissioned - Our VAV units are guaranteed to ship 100% defect free, ready for immediate installation and use. We offer packaging validation and digital pictures to give you peace of mind that your unit has been tested and is ready to go.

Hydronics Coils Assembly - All VAV units include a pressure gauge and are pressure tested overnight to ensure the unit’s integry.

Controls Hardware/Software - Operating parameters, schedule set points, and VAV applications are preloaded into the controller. Commissioning includes testing Leaving Air Temperature (LAT) sensors and running actuators through a full cycle to guarantee correct wiring and operation.

Optimized Logistics - We can stage delivery by zone or quadrant upon request of the project team. We offer special packaging (5 to 8 units per pallet) that minimizes shipping costs and saves on required storage space.

Product Highlights:

- Includes controls, valves, damper, actuators, coil and piping, integrated shipping supports and handles

- Pre-programmed, powered up, pressurized and commissioned

- Prefabricated wiring harness, plug-and-play, UL/ULC 508A

- Shipped from factory 100% defect-free!

- Validation package with pictures of each completed ZCU before leaving factory

- Field-verifiable pressure integrity with a gauge attached, ensuring no leaks

- Plug-and-play product!

Product Specifications

Air:

Access Doors - Low leak hinged with cam lock

Box Liners

Available in:

- Fiberglass

- Foil faced insulation

- Closed cell (EOFI)

- Metal lining

Sound - ARI certified sound ratings

Terminals

- Single duct

- Fan powered

- Underfloor

Water:

Hydronics

- Y-strainer

- ATC valve

- Manual Air Vent

- Balancing Valve

- Pre-assembled & tested

- Custom piping configurations available

Standardization - Piping packages are 6” on center 3/4" pipe with 1/2" control valve regardless of the coil/VAV box size

Construction

- 22 gauge zinc steel

- 14 gauge rigid support handles

- This ensures:

- Simplified installation

- Box durability

- Quieter operation

- Minimal broken airflow pickups

Controls:

Protocol

- BACnet®

- ModBus

- LonWorks

- Wireless

Wireless Frequency

- 315 MHz

- 868 MHz

- ZIGBEE 2400-2483 MHz

Voltage

- 24VAC

- 120VAC

- 277VAC

- 60Hz Only

- 9VA (plus loads)

- Transformer optional (for 120VAC 277VAC)

- Fully NEC and local conduit code compliant

- Actuators - Lab High / Low speed Tracking Exhaust